Ochre Factory

![[Previous]](../../../common/previous.gif)

![[Next]](../../../common/next.gif)

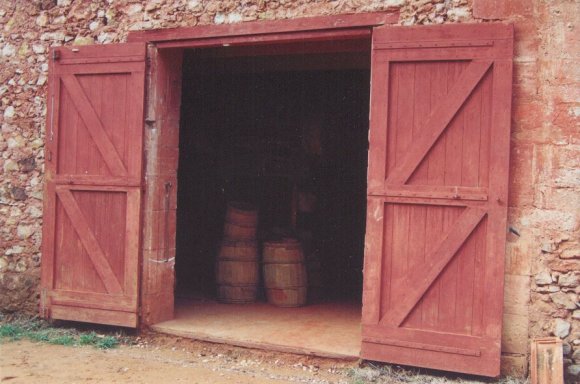

Ochre Factory

After walking all morning, we ended up at the Ochre Factor Museum near Roussillon. Ochre was the basis for paints for centuries before they were overtaken by synthetic paints. The final part of the Ochre processing was the grinding of dried blocks, which were then packaged into barrels like those that you can see above.

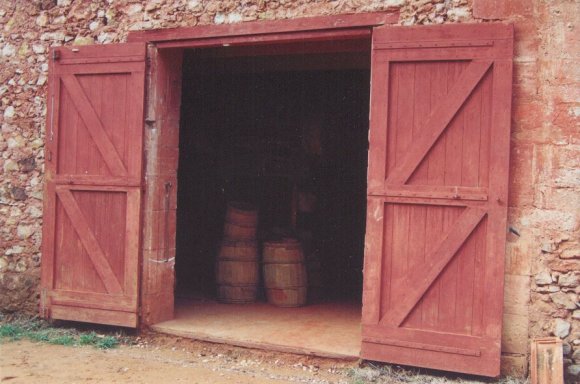

Settling Ponds

The entire process of creating ochre is quite interesting. The raw ochre was mined from local quarries. The raw material consists of approximately 80% sand and 20% ochre. Water is mixed with the ore and then sluices are used to separate the heavier sand from the ochre. Once the separation has taken place, the water/ochre mixture is piped to settling ponds. It would take up to a year for all of the moisture to evaporate.

After a year has passed, the ochre in each settling pond is cut into squares. These squares can then be used directly or they can be dried further in a kiln. If the ochre is dried in a kiln, it changes color as chemical transformations take place during the drying process (iron dioxide is changed into iron oxide). The drying process changes the color of the ochre from red to yellow.